-

Boulons en acier d'écrou

-

Boulon en acier de sortilège

-

Boulon d'acier au carbone

-

Boulons à haute résistance d'acier inoxydable

-

Écrous d'acier au carbone

-

Écrou d'acier inoxydable

-

Joint de produit plat

-

Joints en acier de ressort

-

Joint d'acier inoxydable

-

Goujons entièrement filetés

-

Attaches non standard

-

Ancres séismiques de cale

-

Vis autotaraudeuse

-

Attaches électriques

-

Attaches de panneau solaire

-

Dispositif d'accrochage d'acier inoxydable

-

BOSSARDC'est notre partenaire européen

BOSSARDC'est notre partenaire européen -

LiC'est une bonne affaire

LiC'est une bonne affaire

Boulons en acier d'écrou de la classe 10,9 lourds de haute résistance du sortilège DIN6914

Contactez-moi pour des aperçus gratuits et des bons.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

x| Norme | DIN6914 | Matériel | acier au carbone |

|---|---|---|---|

| Taille | M12-M36 | Finition | NOIR DE ZP YZP HDG |

| Catégorie | 4,8 6,8 8,8-12,8ect | Emballage | Carton et palette ou selon l'exigence du client |

| Échantillon | Aperçu gratuit | Fil | fil machine |

| Délai d'exécution | Par sur quantité d'ordre | Type | Tête d'hexagone |

| Avantage | nous pouvons fabriquer selon la conception de client, OEM/ODM/service adapté aux besoins du client f | OEM | oui, bienvenu |

| Surligner | Boulons en acier de l'écrou DIN6914,Boulons en acier de l'écrou CL10.9,Boulon lourd de tête de sortilège DIN6914 |

||

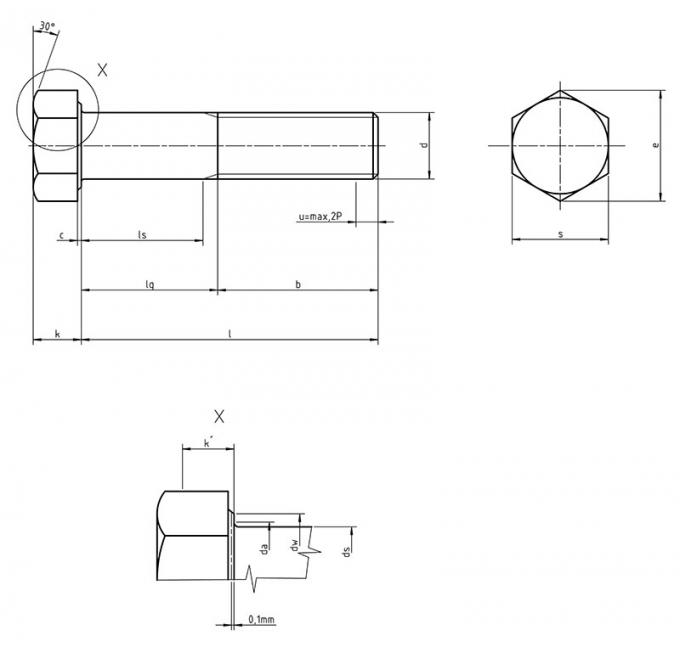

Specification

Structural Hex Head Bolts

DIN 6914 - High-strength injection structural bolts

Current norm: DIN EN 14399-4

Equivalent norms: ISO 7411; PN 82343; UNI 5712; EU 781

Legend:

b - length of the thread (at least)

l - length of bolt

d - the nominal diameter of the thread

k - head height

r - radius

e - the diameter of the circumscribed circle (not less than)

s - size hex head turnkey

c - thickness of the mounting collar

ds - diameter of the screw shank

u - thread run

lg - length of the shank to thread

ls - length of the shank to the start of the thread

da - the maximum diameter of the stem at the head of the screw

dw - minimum diameter of the seat

k´ - minimum size of the head on the key

Makings:QBH HV 10.9

Steel: 10.9

Stainless: -

Plastic: -

Non Ferrous: -

Thread: 6g

Table according to DIN 6914:

| Thread d | M12 | M16 | M20 | M22 | M24 | M27 | M30 | M36 | |

| P | 1.75 | 2 | 2.5 | 2.5 | 3 | 3 | 3.5 | 4 | |

| b (see tab. below) | above tde continuous steped line | 21 | 26 | 31 | 32 | 34 | 37 | 40 | 48 |

| under tde continuous steped line | 23 | 28 | 33 | 34 | 37 | 39 | 42 | 50 | |

| c | Min. | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Max. | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | |

| da | Max. | 15.2 | 19.2 | 24 | 26 | 28 | 32 | 35 | 41 |

| ds | Nomial size | 12 | 16 | 20 | 22 | 24 | 27 | 30 | 36 |

| Min. | 11.3 | 15.3 | 19.16 | 21.16 | 23.16 | 26.16 | 29.16 | 35 | |

| Max. | 12.7 | 16.7 | 20.84 | 22.84 | 24.84 | 27.84 | 30.84 | 37 | |

| dw | Min. | 20 | 25 | 30 | 34 | 39 | 43.5 | 47.5 | 57 |

| e | Min. | 23.91 | 29.56 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | 66.44 |

| k | Nomial size | 8 | 10 | 13 | 14 | 15 | 17 | 19 | 23 |

| Min. | 7.55 | 9.25 | 12.1 | 13.1 | 14.1 | 16.1 | 17.95 | 21.95 | |

| Max. | 8.45 | 10.75 | 13.9 | 14.9 | 15.9 | 17.9 | 20.05 | 24.05 | |

| k´ | Min. | 5.28 | 6.47 | 8.47 | 9.17 | 9.87 | 11.27 | 12.56 | 15.36 |

| r | Min. | 1.2 | 1.2 | 1.5 | 1.5 | 1.5 | 2 | 2 | 2 |

| s | Nomial size = max. | 22 | 27 | 32 | 36 | 41 | 46 | 50 | 60 |

| Min. | 21.16 | 26.16 | 31 | 35 | 40 | 45 | 49 | 58.8 | |

Process flow

Cold forging

Annealing treatment(if need) ➨ wiredrawing ➨ clod forging ➨ thread rolling ➨make heat treatment(if need) ➨ Finish ➨ Packing

Hot forging

Cutting material ➨ hot forging ➨ turning ➨ shrink diameter(half thread) ➨thread rolling ➨ make heat treatment(if need) ➨ Finish ➨ Packing

Product Grade

Class4.8 Class5.8 Class6.8 Class8.8 Class10.9 Class12.9

| NO. | Mechanical or physical property |

Property class | ||||||||||

| 4.6 | 4.8 | 5.6 | 5.8 | 6.8 | 8.8 | 9.8 | 10.9 | 12.9/12.9 | ||||

| D≤16mma | d>16mmb | d≤16mm | ||||||||||

| 1 | Tensile strength Rm,Mpa |

nom.c | 400 | 500 | 600 | 800 | 900 | 1000 | 1200 | |||

| max. | 400 | 420 | 500 | 520 | 600 | 800 | 830 | 900 | 1040 | 1220 | ||

| 2 | Lower yield strength ReL,Mpa |

nom.c | 240 | —— | 300 | —— | —— | —— | —— | —— | —— | —— |

| max. | 240 | —— | 300 | —— | —— | —— | —— | —— | —— | —— | ||

| 3 | Stress at 0,2 % nonproportional elongation Rp0.2,Mpa |

nom.c | —— | —— | —— | —— | —— | 640 | 640 | 720 | 900 | 1080 |

| max. | —— | —— | —— | —— | —— | 640 | 660 | 720 | 940 | 1100 | ||

| 4 | Stress at 0,0048 d non-proportional elongation for full-size fasteners Rpf,Mpa |

nom.c | —— | 320 | —— | 400 | 480 | —— | —— | —— | —— | —— |

| max. | —— | 340e | —— | 420e | 480e | —— | —— | —— | —— | —— | ||

| 5 | Stress under proof load Spf,Mpa |

nom. | 225 | 310 | 280 | 380 | 440 | 580 | 600 | 650 | 830 | 970 |

| Proof Sp,nom/ReL min Or strength Sp,nom/Rp0.2min Or rati Sp,nom/Rpf min |

0.94 | 0.91 | 0.93 | 0.9 | 0.92 | 0.91 | 0.91 | 0.9 | 0.88 | 0.88 | ||

| 6 | Percentage elongation after fracture for machined test pieces,A,% |

min. | 22 | -— | 20 | —— | —— | 12 | 12 | 10 | 9 | 8 |

| 7 | Percentage reduction of area after fracture for machined test pieces,Z,% |

min. | —— | 52 | 48 | 48 | 44 | |||||

| 8 | Elongation after fracture for full-size fasteners,Af |

min. | —— | 0.24 | —— | 0.22 | 0.2 | —— | —— | —— | —— | —— |

| 9 | Head soundness | No fracture | ||||||||||

| 10 | Vickers hardness, HV, F≥98N |

min. | 120 | 130 | 155 | 160 | 190 | 250 | 255 | 290 | 320 | 385 |

| max. | 220g | 250 | 320 | 335 | 360 | 380 | 435 | |||||

| 11 | Brinell hardness, HBW ,F=30D² |

min. | 114 | 124 | 147 | 152 | 181 | 238 | 242 | 276 | 304 | 366 |

| max. | 209g | 238 | 304 | 318 | 342 | 361 | 414 | |||||

| 12 | Rockwell hardness,HRB , HRB |

min. | 67 | 71 | 79 | 82 | 89 | |||||

| max. | 95g | 99.5 | ||||||||||

| Rockwell hardness, HRC |

min. | —— | 22 | 23 | 28 | 32 | 39 | |||||

| max. | —— | 32 | 34 | 37 | 39 | 44 | ||||||

| 13 | Surface hardness HV 0.3 |

max. | —— | h | h,j | h,j | ||||||

| 14 | Height of non-decarburized thread zone,E,mm | min. | —— | 1/2H1 | 2/3H1 | 3/4H1 | ||||||

| Depth of complete decarburization in the thread,G,mm |

max. | —— | 0.015 | |||||||||

| 15 | Reduction of hardness after retempering,HV | max. | —— | 20 | ||||||||

| 16 | Breaking torque, MB,N·m |

min. | —— | in accordance with ISO 898-7 | ||||||||

| 17 | Impact strength, KVK,I,J |

min. | —— | 27 | —— | 27 | 27 | 27 | 27 | m | ||

| 18 | Surface integrity in accordance with | ISO 6157-1n | ISO 6157-3 | |||||||||

|

a Values do not apply for structural bolting. |

||||||||||||

Materials and Chemical compstition

1008

| CHEMICAL COMPOSI % | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | Al |

| 0.06 | 0.06 | 0.33 | 0.013 | 0.003 | 0.01 | 0 | 0.01 | 0.028 |

1035

| CHEMICAL COMPOSI % | |||||||

| C | Si | Mn | P | S | Cr | Ni | Cu |

| 0.34 | 0.13 | 0.73 | 0.012 | 0.002 | 0.02 | 0.01 | 0.02 |

10B21

| CHEMICAL COMPOSI % | ||||||

| C | Si | Mn | P | S | Cr | B |

| 0.2 | 0.04 | 0.81 | 0.017 | 0.007 | 0.017 | 0.0021 |

1045

| CHEMICAL COMPOSI % | |||||||

| C | Si | Mn | P | S | Cr | Ni | Cu |

| 0.45 | 0.23 | 0.58 | 0.014 | 0.006 | 0.057 | 0.008 | 0.016 |

40CR

| CHEMICAL COMPOSI % | |||||||

| C | Si | Mn | P | S | Cr | Ni | Cu |

| 0.4 | 0.21 | 0.54 | 0.015 | 0.008 | 0.95 | 0.02 | 0.02 |

35CRMO

| CHEMICAL COMPOSI % | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | Mo |

| 0.35 | 0.22 | 0.59 | 0.01 | 0.003 | 0.93 | 0.01 | 0.01 | 0.21 |

42CRMO

| CHEMICAL COMPOSI % | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | Mo |

| 0.42 | 0.27 | 0.92 | 0.013 | 0.004 | 1.01 | 0.03 | 0.04 | 0.2 |

Finish

PLAIN ZP YZP BLACK HDG DACROMET GEOMET CHROME NICKEL AND SO ON

PACKING

QBH BULK

20-25KG/CTN,36CTNS/PALLET

20-30KG/BAGS,36BAGS/PALLET

ONE TON/BOXES

50KG/ IRON DRUM,12 IRON DRUMS/PALLET

QBH SMALL PACKING

Packing in small boxes according to customer’s requirements

Packing in plastic bag according to customer’s requirements

QBH PALLET TYPE

SOLID WOOD FUMIGATION PALLET

EURO Pallet

THREE SPLINT PALLET

WOODEN BOX

The advantages of QBH

- QBH brand sales to the main quality assurance.

- Years of export trade management, excellent service, word-of-mouth guarantee.

- By working with TUV,escort for quality.

- Customization of non-standard parts can be made according to customer's requirements and drawings.

- For quality customers,we can provide a certain credit period.

Product application

High-strength Hexagon Head bolts DIN 6914 are intended for use in GV and SL structural steel bolting in accordance with 18 800 part 1,together with DIN6915 Hexagon nuts and DIN 6916,DIN6917 or DIN6918 washers.